Oil contamination occurs when dirt, metal particles, and other debris accumulate in oil. Over time, undetected contaminants can damage components and even lead to machine failure.

To help solve this invisible problem, oil cleaning systems are used in the manufacturing, offshore, shipping, heavy vehicles, and energy industries. By removing contamination from oil, cleaning systems can reduce or eliminate oil changes, increase machine lifetime, and reduce operating and maintenance costs.

We talked with Dr. Peter Büscher, application specialist at Evident, to learn more about the importance of oil cleaning and how the cleanliness of oil is analyzed.

Q: What problems are caused by dirty oil?

Peter: Microparticles, moisture, and salt cause oil to lose its lubricating qualities, leading to corrosion, additive degradation, and the formation of resins and deposits. This causes mechanical parts―such as valves―to jam, seize up, and become worn, which leads to costly, time-consuming repair and maintenance work. In the past, the wasted oil was simply discarded once it became contaminated or oxidized. This was a waste, as oil can last forever—you just need to know how to clean it.

Q: Can you explain the effects of contaminants on oil?

Peter: Oil has an “invisible problem” due to contaminants, so it needs to be changed regularly and machine parts continue to break down. We are so used to this process that we don’t think it can be done another way. But if oil can be kept 100% clean, then in theory it should never degrade or require changing. Machine parts could be used indefinitely. The risk of breakdown and production downtime would be drastically reduced.

The oil filter built into most machines protects against large particles that can cause direct damage to machine components. There are only a few large, dangerous particles in oil. Most particles in oil are exceedingly small. However, research has shown that these microparticles bind with other contaminants and accelerate oxidation in the oil. This causes the oil to lose its lubricating qualities and leads to the formation of resins and deposits. These form a sticky surface that eventually causes valves and moving mechanical parts to jam and seize up.

New machines are manufactured to far stricter tolerances than older machines, which makes them more sensitive. Modern machines require a much cleaner oil and regular cleaning of the system so that they are not affected by breakdowns.

Q: How do systems clean oil?

Peter: Oil cleaning systems are like a human kidney, gradually cleaning the lubricant every time it passes through the system―until it is spotless. For instance, some oil cleaning systems effectively remove water and solid contaminants from oil.

|  |

Oil cleaning systems. Images courtesy of Europafilter Norge. |

When oil is ultra-cleaned, oxidation ceases. Without oxidation the oil keeps all its desired qualities and, in theory, never needs to be changed.

Q: What are the benefits of integrating an oil cleaning system into the production process?

Peter: Not having to change oil saves money, of course, but the large savings come from the increased uptime of machinery. Studies by Electric Power Research Institute have concluded that over half of the forced outage hours related to bearings, journals, and lube oil systems were due to contaminated oil.

Completely clean oil also reduces wear on valves, cylinders, bearings, and other affected components in a machine. Over time this can lead to significant savings in maintenance costs.

Q: The impact of oil on the environment is an important topic in the conversation around combating climate change. How does cleaning oil reduce waste?

Peter: Waste oil is poisonous. It is more poisonous than new oil and can have a mutating effect on the smallest organisms in the food chain. Each liter of discharged oil gives rise to both costs and negative environmental effects.

The amount of poisonous discharged oil can be reduced to the same extent if clean oil continues in use. With an oil cleaning system, industries can save money while taking action to help the environment.

Q: You’ve explained the importance of removing contaminants such as microparticles, moisture, and salt from oils. Is it important to further analyze these contaminants?

Peter: Yes, a regular oil analysis enables long-term oil status monitoring, leading to a clear trend analysis of the system status. Analyzing this data identifies problems, increases machine lifetime, reduces operating and maintenance costs, facilitates predictive maintenance, and preserves productivity.

Q: Why it is necessary to perform detailed oil analyses? Are the oil contaminants that dangerous to a system?

Peter: Yes, contaminants can have an enormous impact. Oil fulfills many roles in a system. Just think of a gear or a hydraulic system. The main purpose of oil is to lubricate and separate parts (e.g., in gear boxes or sliding mechanical parts) and transfer power (e.g., hydraulics or gear boxes).

Oil also cleans, as it picks up the contaminants and transports them to the filter before collecting in the oil reserve to be used once more. Oil also acts as a coolant or heat transfer fluid and absorbs water and moisture.

Finally, oil prevents corrosion, oxidation, and foaming in the system. Knowing the various roles of oil, it becomes clear that clean oil is important to the entire system. If oil is contaminated, this finally leads to higher operation as power, heat, and noise increase, and maintenance costs due to wear of mechanical components and maintenance stoppage.

Q: How do you obtain reliable data from oil analyses?

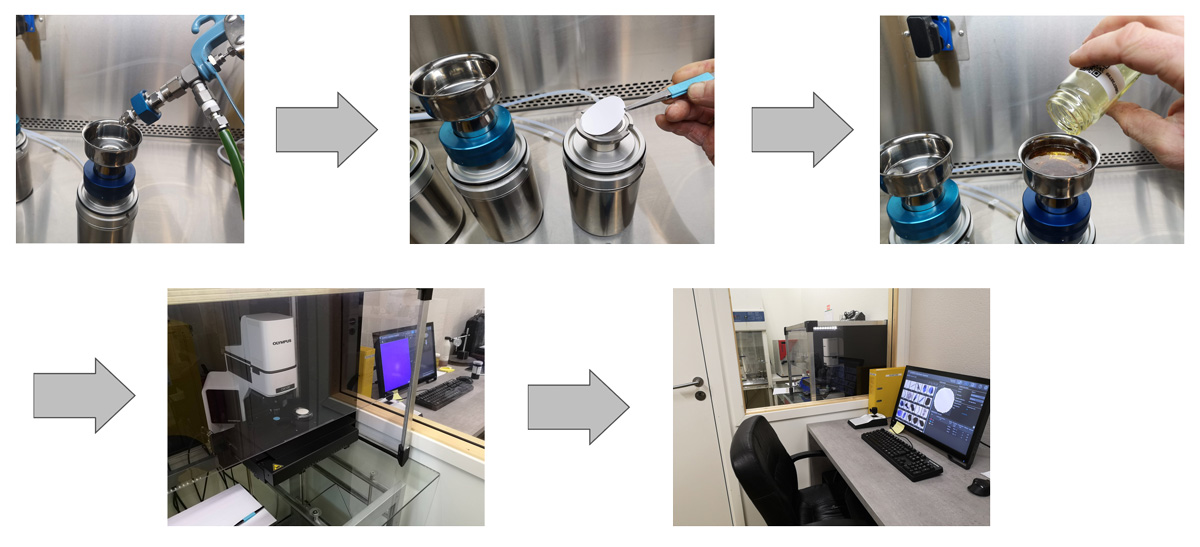

Peter: When you run an oil analysis, it includes a few preparation and inspection steps. You need to “think cleanliness” at every moment during your sample prep and analysis steps. Only when all steps are conducted with cleanliness, accuracy, and the highest care, will you get reliable data.

Example oil analysis process from sample prep to particle review. Image courtesy of Europafilter Norge.

Q: What types of oil analysis systems are in the market?

Peter: The conventional method used to inspect oils for particulates is a laser-based automatic particle counter (APC). However, APC measurements don’t supply details about the shape of particles (e.g., fibers) or whether they are reflecting (e.g., metal) or non-reflecting. Also, laser-based particle counters often overlook transparent particles or overcount due to bubbles in the liquid.

For a comprehensive overview of particulates in an oil sample, microscope-based particle inspection systems offer various advantages over APCs. This method is important as cleanliness standards demand detailed information about the nature of the contamination, such as the number of particles, particle size distribution, and particle characteristics.

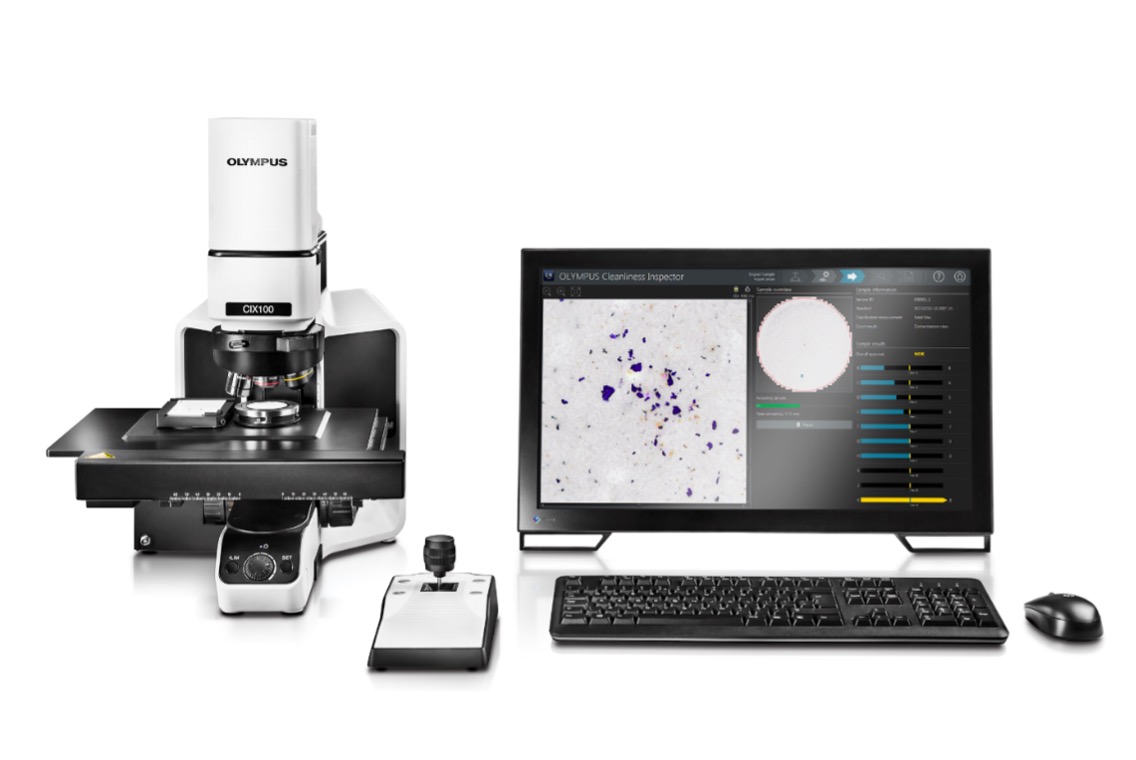

The OLYMPUS CIX100 cleanliness inspector is a microscope-based system for oil analysis

Q: There is a trend of inline oil inspections. How does this affect microscope-based analysis?

Peter: One of the current trends in oil analysis is inline oil quality. There are some benefits and disadvantages. With inline oil quality monitoring, you will get instant oil quality values trending over time and can easily share the results in a cloud-based presentation. On the other hand, the results aren’t that accurate―with incorrect data especially at low ISO values or dirty oil. Plus, you occasionally need to verify the results through lab analysis. A microscope-based system, such as the OLYMPUS CIX100 technical cleanliness system, offers results that can be copied to a cloud for trend analysis.

Trend analysis for oil quality values. Image courtesy of Europafilter Norge.

Q: The OLYMPUS CIX100 system is dedicated to technical cleanliness. Why is this system ideal for oil analysis?

Peter: The OLYMPUS CIX100 system has a fixed system setup that requires only minimal adjustment by the user. The seamless integration of hardware and software enables users to achieve a high throughput and reliable, accurate data.

Another important benefit is maximized automation, which helps reduce user error and increase throughput. The fully automated system offers reproducible imaging conditions that enhance image quality and provide excellent repeatability, reproducible positioning, and integrated calibration. The step-by-step software guidance reduces inspection and process time, cuts down on handling errors, and minimizes user interaction.

An effective inspection system should also provide the user with the ability to analyze samples in real time. In the case of the OLYMPUS CIX100 system, a novel polarization method enables live analytics of both reflective and non-reflective particles ranging from 2.5 µm to 42 mm. This unique all-in-one scanning solution enables particle scans to be completed twice as fast compared to other inspection systems that require two separate images. The live display of counted and sorted particles into size classes lets users make immediate decisions about reprocessing. This saves valuable time, since inspection issues can be addressed as quickly as possible.

The OLYMPUS CIX100 system offers powerful, easy-to-use tools for revising inspection data, as well as repeatable results and a guided particle review. Thumbnail images of all detected contaminants are linked with their dimensional measurements for simple particle review and revision. This clear representation of all relevant inspection data, combined with support for international standards, offers maximum time savings and flexibility.

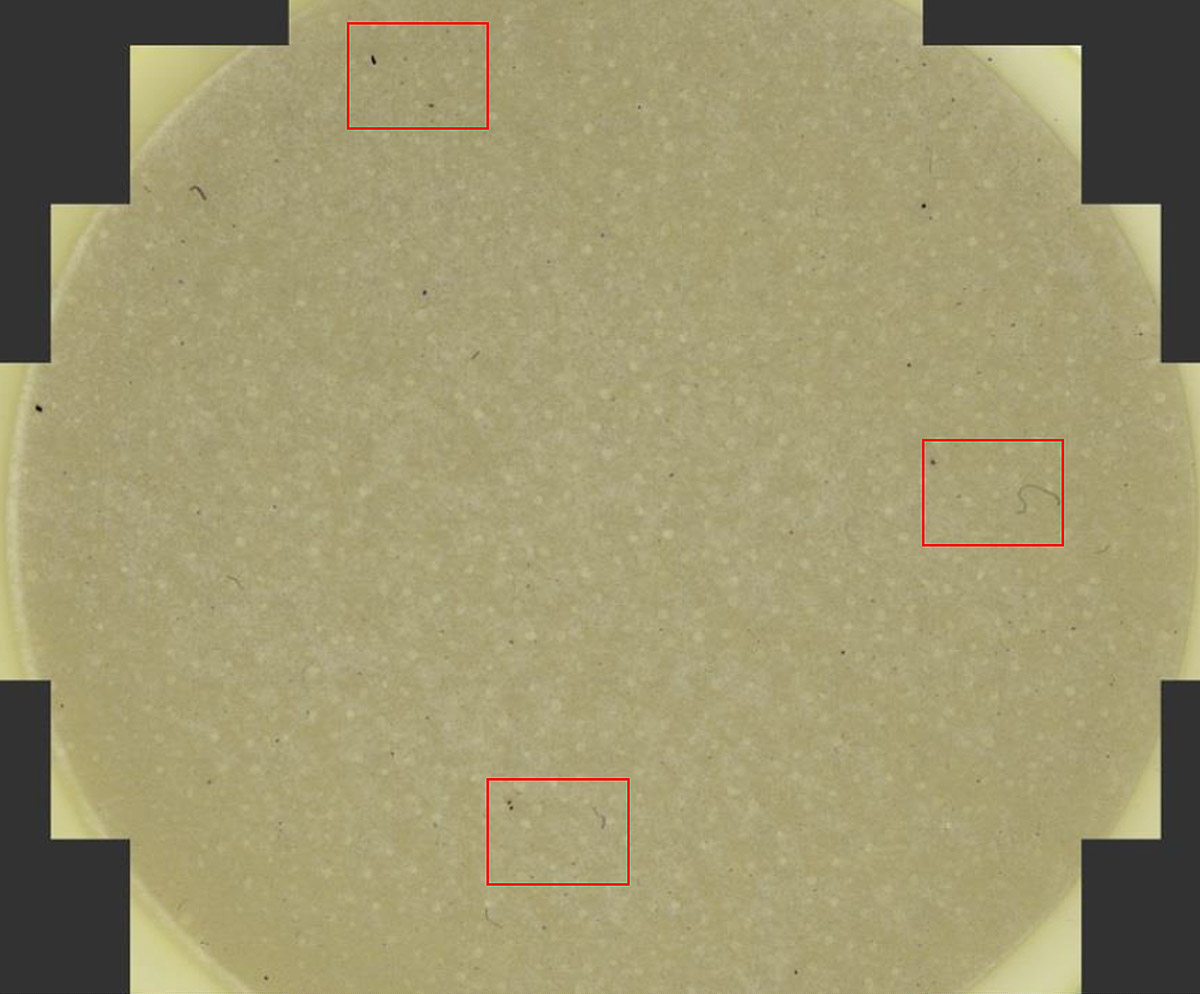

User interface of the OLYMPUS CIX100 technical cleanliness system. Image courtesy of Europafilter Norge.

Other benefits are the intuitive software interface and the resolution it offers. You can see particles easily from 15 µm and 5 µm as requested by ISO 4406 for microscopes. And most of all, the system has exact counting and offers live analysis. There is no extrapolation, and the system counts every frame on the sample. See the following picture as an example.

Example of extrapolation

Extrapolation from samples can lead to a bad particle count. For instance, when systems only scan three frames on the sample and count the contaminants inside these frames. The results are then multiplied by the area of the sample. This concept can lead to incorrect results, as the particles are not covered on the sample. This could lead to particle counts that are too high or too low.

With the OLYMPUS CIX100 system, it is also possible to snap detailed particle images. And it is fast, as the system can acquire reflecting and non-reflecting particles in one scan. Finally, the system has an integrated database and editable reports included. Even inexperienced operators can quickly create reports that follow company and industry standards. Time is saved, effort is reduced, and results and issues are quickly addressed.

Related Content

Analyzing Oil Cleanliness in Power Generation Plants Using the OLYMPUS CIX100 System

Maximize Precision in Industrial Particulate Inspections

7 Capabilities That Make Technical Cleanliness Inspections Easy for Novice Operators

Get In Touch

.jpg?rev=336E)